Car engines always run best with cool air, and draw outside air in through an air intake hose past the air filter and through the MAF sensor and to the throttle body.

Some cars are fitted with a cold air intake heat shield, to minimise the amount of heat dissipated by the running engine being introduced into this stream of air.

In the Alfa Romeo 147 for instance, a piece of heat-insulating fabric is installed just over the air intake inlet, which is found at the far left end (next to the car battery) under the hood. The air intake could be at different locations under the hood for different car models.

After some time, as the fabric gets older, it becomes soft. Small pieces on the underside may also break off and get inadvertently sucked into the air intake.

These pieces, should there be any, will be caught by the air filter along the way. This is not a cause for critical concern, just that the air filter will need to be replaced or cleaned more frequently.

What is more of a concern is when the heat shield fabric becomes too soft, and it gets sucked in by the strong suction during throttle.

The fabric is screwed onto the chassis of the car, so it will not be completely sucked in, but with the heat shield blocking the way of the airflow, you may find your car’s performance adversely affected.

This will be indicated by a loss of power, some flat spots in the lower gears, and if bad enough, even some sputter like the engine is gasping for air. It will be noticeable.

So, should the heat shield be completely removed and the car run without it in place? Well, I’ve tried that once and the car’s performance took a noticeable dip.

There is a reason for the heat shield being there in the first place, and quite an important purpose for it to remain there. Of course, such a fabric could always be replaced, but in my case, I chose to reuse.

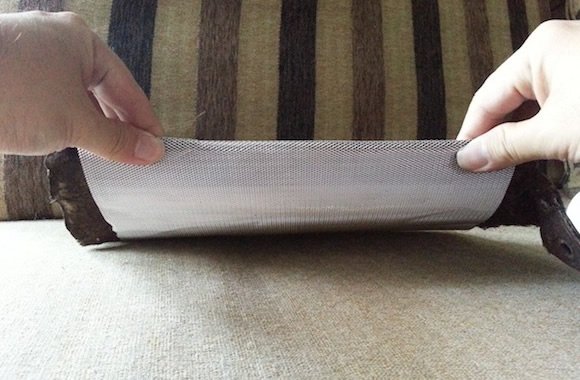

In order to do that, the fabric had to be reinforced slightly.

To perform this task, we will need a few items and tools:

Philips screwdriver (to remove and replace the heat shield on the car)

- A pair of pliers

- A normal stationery stapler (optional)

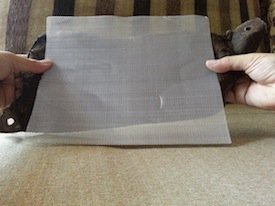

- Aluminium wire mesh

Let’s proceed!

First, locate the heat shield under the hood of the car. Once you’ve found it, remove all screws or mounting holding the heat shield in its place.

|

|

|

|

|

|

|

|

|

|

After a week of driving, check the fabric to ensure that everything is still in its rightful place – that the fabric has not collapsed or been dislodged, and that the aluminium mesh has not detached itself from the fabric.

I have driven the car for months now, and the whole setup has not moved from its position. At least now, I know for sure my cold air intake will not be blocked by a fabric which collapses under its own weight or gets sucked in by the throttle, and that the heat shield fabric will still be minimising hot air from the engine bay from entering into the air intake.

Of course, some may argue that the fabric could already be too old to have proper insulating properties for its function, and that it would be best to replace the heat shield fabric altogether; but this is a quick fix for those who want an alternative. Or for cases when such a fabric cannot be easily sourced or replaced.

See also:

- Alfa Romeo – How to Reset ECU and Throttle

- Alfa Romeo – Installing K&N Air Filter

- Alfa Romeo – Cleaning the MAF Sensor

Other related sites of interest:

- Alfa Romeo main website

- Alfa Romeo USA

- Alfa Romeo Canada

- Alfa Romeo UK

- Alfa Romeo New Zealand

- Alfa Romeo at Car and Driver

- Alfa Romeo on Wikipedia