A multi-tool is something I didn’t expect to buy, at least I’ve not thought of a use for it, until I saw one in action.

The way it handles plunge cuts into various materials is amazing, and one can already envision the many ways a multi-tool would make light of work which would otherwise become tedious, lengthy and difficult.

I was in the active process of collecting Milwaukee’s M12 series of 12V cordless power tools in mid-2014, and didn’t need much convincing to add the Milwaukee M12 Multi-Tool to my arsenal of existing appliances on the M12 system.

Despite not having used one before, I was convinced that a multi-tool is an essential sibling of the versatile rotary tool, the Milwaukee M12 Rotary Tool and the Black & Decker RTX-1 High-Speed Rotary Tool.

At A Glance

First impressions upon arrival of the Milwaukee M12 Multi-Tool 2426-20:

|

|

|

|

|

|

|

|

I bought the Milwaukee M12 Multi-Tool bare-tool only version, as I already have a number of M12 lithium-ion batteries and charger from my M12 CPD-202C Hammer Drill Driver.

Milwaukee makes it easy to own many of their similar cordless power tools without needing to spend too much unnecessarily. I foresee that other manufacturers of power tools will take this path in due course, with some such as Bosch already starting with their 10.8 V power tools.

As indicated by the last two digits “20” in the model no. 2426-20, this Milwaukee M12 Multi-Tool set comes as a bare tool without any battery, but with a limited set of accessories, including a plunge cut wood saw blade and sanding pad with sanding sheets of various grit levels.

Any battery that you see in this article came from one of my other set of Milwaukee M12 power tool.

Using the Milwaukee M12 Multi-Tool

|

|

|

|

|

|

|

|

|

|

|

|

|

Like the rotary tool, a multi-tool’s efficacy is only as good as the number of tool attachments and accessories available at its disposal. Since this set came with minimal attachments, I searched online and bought this 47-piece set of comprehensive blade attachments (see left) for the multi-tool. These third party blades can be found in the links given at the end of this article. |

|

|

The Milwaukee M12 Multi-Tool has 12 speed settings which command its powerful 12V motor to deliver between 5,000 to 12,000 oscillations per minute.

The oscillations are very slight – at only 1.5 degrees to each side left and right – just a minuscule 3 degrees overall as it sways from far left to far right and back. Seen with the naked eye, a blade attached to it would seem like it was only vibrating in place, but it is actually making very fast sawing motions about its pivot point.

Pushing an oscillating saw blade at five-digit cycles per minute against wood or plasterboard results in very speedy cuts into the material.

With a narrow blade such as the one that came with the set, it is easy to make small cuts in tight spaces, spaces where a conventional saw may find it difficult or impossible.

|

|

The plunge saw blade can be used to make plunge cuts into plasterboard or partition walls, making it easy to cut square or rectangular holes for power socket outlets and receptacles.

With the M12 Multi-Tool, this kind of holes can now be cut without first drilling a hole at one or all four corners before sawing, which is normally done prior to saw-outs with a conventional saw. This can be done in both plasterboard and wood.

|

|

With the right attachments, the Milwaukee M12 Multi-Tool can also be used to saw metal pipes and conduits. This requires the bimetal types of saw blades, which can be purchased separately.

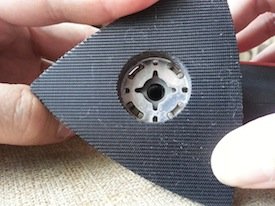

Although Milwaukee sells a set of these, most OEM blades available in the market may also be used, as the M12 Multi-Tool set comes with a universal adapter that allows it to be compatible with other blades which you may already own from a different multi-tool.

|

|

Like its sibling the M12 Rotary Tool, the M12 Multi-Tool is an indispensable tool suitable for the remodeller, electrician, maintenance repair technician, flooring contractor, casual woodworker and DIY enthusiast.

A multi-tool can accomplish cuts in under a minute which could otherwise take over 10 minutes to complete. Due to short blade profiles and unique manner of oscillations, the M12 Multi-Tool can go where most other tools can’t go, and it’s left to the imagination of the tool user how best to deploy it to action.

|

|

The Milwaukee M12 Multi-Tool runs on the M12 REDLITHIUM Battery which delivers up to 25% more runtime than the competition.

A fuel gauge is found just above the speed setting wheel, giving the user an indication of how much charge is left in the battery. These REDLITHIUM batteries fully charge in 30 to 40 minutes, so downtime is not something you’ll often encounter with a spare battery or two.

|

|

Specifications

| Specifications | Technical Data |

|---|---|

| Operating battery voltage | 12 V Lithium-ion |

| Oscillation angle | 3o end-to-end, i.e. 1.5o each side |

| Speed | 5,000 – 20,000 oscillations per minute |

| Variable speed dial | 12 speed settings |

| Length | 10-¼” |

| Weight | 1.63 lbs |

The Milwaukee M12 Multi-Tool in Action

Conclusion

Recently, I was hired to remove a stretch of glass panels and a glass door in an office renovation job. This left a strip of silicone on the partition wall which had to be removed.

My hired hand tried to work the strip out by scraping it with a metal scraper. It was obvious from the amount of energy expended, the sweat pouring down on his forehead and cheeks, and the constipated look on his face that this was no easy endeavour.

I took the Milwaukee M12 Multi-Tool out, attached a suitable scraper, and took it off the wall with absolute ease (right). The Multi-Tool was indeed invented for a job like this. Definitely.

I use the Milwaukee M12 Multi-Tool mostly for making special plunge cuts into wood and into plaster walls and ceilings.

While it is capable enough to cut pipes and conduits ranging from PVC to copper and EMT, I would normally use the Milwaukee M12 Hackzall Recip Saw instead.

However, if the pipe needs to be flush cut to the surface, the Milwaukee M12 Multi-Tool is there for a perfect job!

SEE ALSO:

- Milwaukee M12 Fuel Hammer Drill Driver CPD-202C

- Milwaukee M12 Fuel Hackzall Reciprocating Saw

- Milwaukee M12 Jigsaw

- Milwaukee M12 Rotary Tool

- Milwaukee M12 Compact Vacuum

- Milwaukee Magnetic Tape Measure